Core Advantages of MRAM in Aerospace: Radiation Hardening, Unlimited Read/Write, and Low Power Consumption

With its unique properties of radiation hardening, unlimited read/write endurance, and low power consumption, MRAM is becoming the preferred choice for next-generation aerospace memory. This article will provide an in-depth analysis of MRAM's key advantages and applications in the aerospace field.

According to ESA statistics, 40% of satellite failures are caused by radiation-induced memory errors. Due to its radiation-hardening and other features, MRAM is becoming the preferred solution for next-generation aerospace memory.

Why Do Aerospace Applications Need Specialized Memory?

In the days before MRAM technology, circuit boards in aerospace equipment typically used DRAM or SRAM that had been radiation-hardened by chip manufacturers. These were combined with solutions such as multiple redundancy (storing the same data in multiple memories, and correcting data if it was corrupted by radiation), ECC (Error-Correcting Code) algorithms (using a combination of software and hardware to calculate checksums for data, which can be used to repair radiation-induced changes), and watchdog timers (using a hardware timer to periodically check the status of the memory and automatically trigger a reboot if a radiation event causes the processor to enter an error loop).

These solutions rely heavily on hardware-software co-design. Specifically, multiple redundancy and ECC require significant MCU computational power, which could otherwise be allocated to "proper" flight data calculations. This is where MRAM technology comes in.

Why Choose MRAM?

The biggest advantages of MRAM are its radiation hardening, low power consumption, long lifespan, and unlimited read/write endurance.

Radiation Hardening

Spacecraft are constantly exposed to high-energy cosmic rays and charged particles, which can disrupt or destroy data in traditional memory types like SRAM and DRAM. MRAM uses magnetic materials to store data. The magnetic domain direction cannot be altered by electrical charge disturbances caused by cosmic rays, which is the fundamental reason for MRAM's natural radiation hardening.

A 2019 NASA report indicated that near-Earth orbit satellites experience over 5,000 single-event upset events annually, with 23% of these leading to critical data corruption.

The Principle of Radiation Hardening

Traditional DRAM and SRAM store data based on electrical charge (e.g., charge for '1,' no charge for '0'). High-energy radiation in space creates a large number of electron-hole pairs, which can lead to:

- Single Event Upset (SEU): The charge state in a memory cell is altered, causing a data flip from '1' to '0' or vice versa.

- Single Event Latch-up (SEL): A low-resistance path is created in CMOS devices, leading to a large current flow that can burn out the chip.

Because MRAM relies on the magnetization direction of magnetic domains, rather than charge, it has an inherent ability to resist radiation.

Diagram Explanation:

- Fixed Magnetic Layer / Reference Layer: The magnetization direction of this layer is permanently fixed (the red layer in the diagram, with magnetization pointing to the right).

- Its magnetic material is specially treated with high coercivity, making it resistant to external magnetic fields or radiation disturbances.

- Tunnel Barrier Layer:

- An extremely thin insulating layer, typically made of magnesium oxide (MgO) or aluminum oxide (AlOx).

- It separates the fixed and free magnetic layers but allows electrons to pass through via quantum tunneling.

- Free Magnetic Layer:

- The magnetization direction of this layer can be changed (the blue layer in the diagram).

- It has lower coercivity and its magnetization direction can be altered by a write current or magnetic field.

- Data Storage:

- Data '0' (Anti-Parallel): When the magnetization direction of the free layer is opposite to the fixed layer (one to the left, one to the right), the MTJ (Magnetic Tunnel Junction) has high resistance.

- Data '1' (Parallel): When the magnetization directions of the free layer and fixed layer are the same (both to the right), the MTJ has low resistance.

- Data is read by detecting the high or low resistance of the MTJ.

Radiation Performance Testing

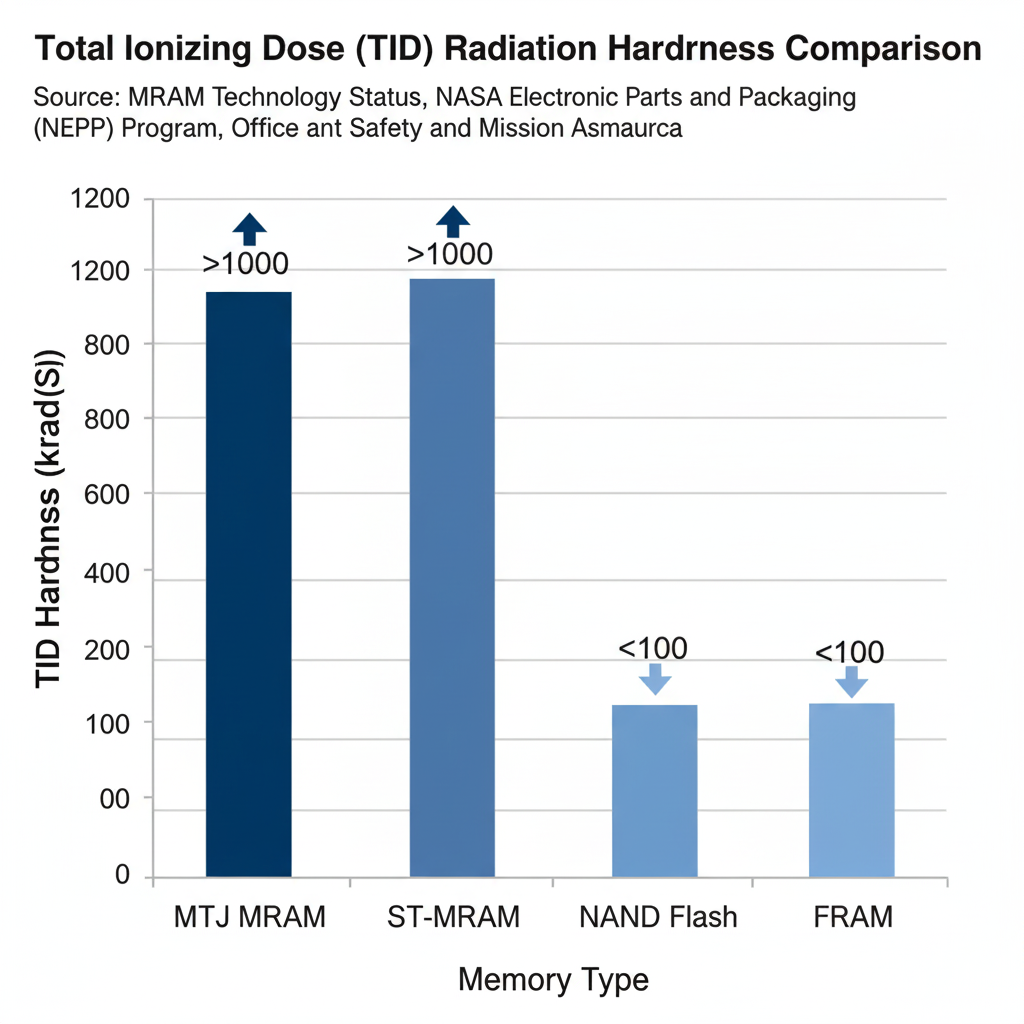

Magnetic Random Access Memory (MRAM) is gaining significant attention in aerospace, military, and other fields with strict reliability requirements due to its non-volatility, high speed, and low power consumption. In these high-radiation environments, MRAM's radiation hardening capability is critical. MRAM's radiation performance testing primarily focuses on two aspects: Total Ionizing Dose (TID) and Single Event Effect (SEE).

Total Ionizing Dose (TID)

TID refers to the cumulative effect on a material and device performance when they are exposed to ionizing radiation (such as X-rays, gamma rays, protons, and electrons) over a long period.

- TID Mechanism: As ionizing radiation passes through a device's materials, it creates electron-hole pairs. These electrons and holes are trapped in insulating layers (like silicon dioxide) or at interfaces by an electric field, leading to a build-up of charge within the device.

- Effect on the Device: This charge build-up can cause shifts in transistor threshold voltages and an increase in leakage currents, affecting the device's normal operation. When the accumulated charge reaches a certain level, the device may fail.

MRAM's memory cells are primarily composed of Magnetic Tunnel Junctions (MTJ), which operate based on magnetic resistance change, not charge. Therefore, MRAM has stronger resistance to TID compared to traditional charge-based memories (such as SRAM or DRAM). However, the peripheral CMOS circuitry of the MRAM chip can still be affected by TID. This peripheral circuitry requires hardening through redundant designs or silicon-on-insulator (SOI) processes (such as Honeywell's RAD-PRO technology) to withstand TID effects.

Single Event Effect (SEE)

SEE refers to the phenomenon where a single high-energy particle (such as a heavy ion, proton, or neutron) interacts with a semiconductor device, generating a large number of electron-hole pairs in a very short time, which causes an instantaneous or permanent change in the device's function.

- SEE Mechanism: When a high-energy particle passes through a semiconductor material, it ionizes a large amount of charge along its path, creating a high-charge-density region. If this charge is collected by a sensitive node, it can instantly change its potential.

- Effect on the Device: SEE can cause a variety of problems, including:

- Single Event Upset (SEU): An instantaneous change in data in a memory cell, but the device itself is not damaged. This is the most common SEE phenomenon.

- Single Event Latch-up (SEL): Triggers a parasitic thyristor structure to turn on in a CMOS device, causing a large current to flow, which can permanently damage the device.

- Single Event Burnout (SEB): In high-power devices, a large current can cause localized overheating, leading to permanent device failure.

- Single Event Gate Rupture (SEGR): A high-energy particle penetrates the gate oxide layer, causing a short circuit or permanent damage to the gate.

MRAM's memory cells themselves are highly immune to SEE. Because their memory state relies on magnetic domain direction rather than charge, the instantaneous charge generated by a single high-energy particle cannot change the magnetic polarity of the domain, and thus SEU does not occur. This gives MRAM a significant advantage in applications requiring high reliability. However, the peripheral CMOS circuitry of MRAM can still be affected by SEE. Therefore, hardening techniques, such as redundant circuits and Error Detection and Correction (EDAC), are typically used in the design to ensure the entire chip's SEE resistance.

| Manufacturer | SEU (MeV·cm²/mg) | SEL (MeV·cm²/mg) |

|---|---|---|

| Everspin | >100 | >84 |

| Aeroflex | >100 | >100 |

(Ref: MRAM Technology Status | NASA Electronic Parts and Packaging (NEPP) Program Office of Safety and Mission Assurance)

The James Webb Space Telescope (JWST) uses Everspin's 16Mb MRAM (model MR4A16B) as cache for its attitude control system. During a strong solar flare in 2022, it operated with zero errors, while traditional SRAM triggered ECC correction 4 times, delaying system response by 12ms.

Non-Volatility, Low Power, and Unlimited Read/Write Endurance

In addition to radiation hardening, non-volatility, low power, and unlimited read/write endurance are MRAM's general advantages.

| Feature | MRAM (Magnetoresistive Random Access Memory) | SRAM (Static Random Access Memory) | DRAM (Dynamic Random Access Memory) | NAND Flash |

|---|---|---|---|---|

| Non-Volatile | Yes (Data stored via magnetization direction, preserved without power) | No (Data stored via charge, lost without power) | No (Data stored via capacitance, requires constant refresh, lost without power) | Yes (Data stored via charge, preserved without power, but requires erase before write) |

| R/W Speed | Fast (Close to SRAM speed, nanoseconds) | Very fast (Nanoseconds) | Fast (Nanoseconds, requires refresh) | Slow (Read in microseconds, write/erase in milliseconds) |

| R/W Endurance | Unlimited (Theoretically unlimited read/write cycles) | Unlimited | Unlimited | Limited (Typically 10k - 100k erase/write cycles) |

| Power Consumption | Low (Low R/W power, zero standby power) | High (Requires continuous power to retain data) | Medium (Requires continuous refresh) | Low (Low R/W power, zero standby power) |

| Cell Structure | Complex (MTJ structure) | Complex (6-8 transistors) | Simple (1 transistor + 1 capacitor) | Simple (1 floating-gate transistor) |

| Storage Density | Medium | Low | High | Very high |

| Radiation Hardening | High (Based on magnetism, insensitive to charge disturbances) | Low (Susceptible to charge flips from radiation) | Low (Susceptible to charge flips from radiation) | Low (Susceptible to charge flips from radiation) |

Non-Volatile

In aerospace, flight logs need to be preserved even after power is lost. Unlike SRAM and DRAM, which require continuous power to retain data, MRAM can keep data intact even when the power is off.

Fast R/W Speed and Unlimited Endurance

Although Flash memory is also non-volatile, its read/write speed is relatively slow, and it has a limited erase/write endurance. This makes Flash unsuitable for applications that require frequent writing, such as high-frequency data logging, caching, or real-time operating systems. MRAM, with its near-SRAM read/write speeds and unlimited endurance, combined with its non-volatility, fills the gap between SRAM/DRAM (fast, but volatile) and Flash (non-volatile, but slow and limited endurance).

Low Power Consumption

Due to its non-volatility, MRAM consumes almost no power in standby mode, as it does not require continuous refreshing like DRAM or continuous power like SRAM to retain data. This is a huge advantage for battery-powered devices (like IoT devices, wearables) and spacecraft where power resources are precious.

Real-World Case Studies

MRAM is used in aerospace applications such as satellite attitude control, Mars rovers, and launch vehicles.

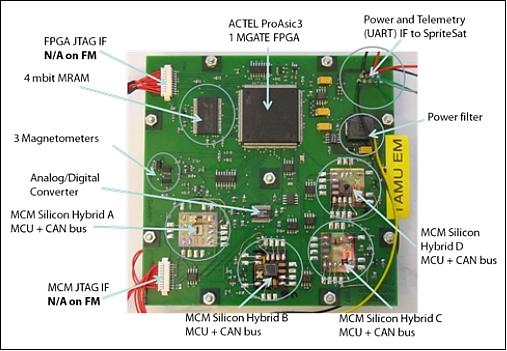

Tohoku-AAC MEMS

The Tohoku-AAC MEMS Unit (TAMU) was developed in collaboration between the Swedish MEMS company Angstrom Aerospace Corporation (AAC) and the Department of Aerospace Engineering at Tohoku University in Japan. The complete TAMU unit is shown in Figure 6.1-1. This unit was deployed on Sprite-Sat, which entered a 680 km polar orbit as a secondary payload of the Japanese Aerospace Exploration Agency (JAXA) satellite IBUKI. AAC's main goal was to evaluate the performance of its thin-film metallization and flip-chip bonding technologies, but the TAMU also used a variety of commercial components, including Everspin MRAM, BME (Base Metal Electrode) capacitors, and an Actel ProASIC FPGA.

NASA Missions

NASA and its partner organizations, such as the Jet Propulsion Laboratory (JPL), have been evaluating and using MRAM. Due to the unavoidable radiation environment in space missions, NASA highly values MRAM's high reliability. MRAM is commonly used for:

- Data Storage: To store critical firmware, program code, and configuration data on spacecraft.

- Black Box: MRAM's non-volatility and high endurance make it an ideal choice for recording flight data and telemetry information, as it can retain data even in the event of a power failure or a severe incident.

- Instant-on: In systems that require fast startup and reconfiguration, MRAM can store the boot code, enabling nearly instantaneous power-on response.

MRAM Manufacturers

Everspin, Honeywell, and Aeroflex are dedicated to the research and production of MRAM.

Everspin Technologies

As of 2025, Everspin is a commercial pioneer in MRAM technology. It originated from the MRAM division of Freescale (now acquired by NXP) and launched its first commercial MRAM product as early as 2008. This first-mover advantage has allowed the company to accumulate extensive experience and intellectual property in technology research and development, product iterations, and market applications.

While other major manufacturers focus more on eMRAM (embedded MRAM), Everspin dominates the discrete MRAM chip market. This means they produce standalone memory chips that can be directly integrated into circuit boards, meeting the needs of customers with specific requirements for high-performance, non-volatile cache or data storage.

These discrete products have found niche applications in industries such as industrial automation, enterprise-level storage, aerospace, and high-performance computing, where data integrity, read/write speed, and reliability are critical.

Everspin currently manufactures two main types of MRAM:

| Technology Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Toggle MRAM | The earliest commercially available MRAM technology. Data is written by using an external magnetic field to change the magnetization direction of the free layer. | - Relatively simple structure | - High write current, requires strong external magnetic field - Low storage density - Write operations can interfere with adjacent cells |

| STT-MRAM | The mainstream MRAM version. Data is written by a spin-polarized current passing directly through the Magnetic Tunnel Junction (MTJ). | - Low write current, low power consumption - Write operations only affect a single cell, leading to high storage density - Fast write speed | - Write voltage affects device reliability - Write power still has room for optimization |

3D Plus specializes in providing high-reliability, radiation-hardened memory modules for aerospace applications, which integrate bare MRAM dies from companies like Everspin. Their MRAM modules are used in multiple projects for the European Space Agency (ESA) and other national space agencies.

Honeywell

Honeywell is a leading global diversified technology and manufacturing company with business in aerospace, building technologies, specialty materials, and safety and productivity solutions. As a giant in the aerospace sector, Honeywell provides advanced avionics, engine systems, and solutions to aircraft manufacturers, airlines, airports, and governments. The company has a long history of developing high-reliability and radiation-hardened electronic components, especially for military and space applications.

Honeywell's MRAM products are typically embedded memory solutions, integrated into more complex avionics modules or spacecraft computers. Their product models often include designations like "HT," "S," or "M," indicating high reliability or military/aerospace grade.

- Avionics Data Storage: Honeywell uses MRAM in its flight control systems, navigation equipment, and mission computers to store flight procedures, configuration data, and log information.

- Spacecraft Memory Modules: Honeywell provides MRAM solutions to NASA and other space agencies for use in satellite on-board computers and data processing units, ensuring data integrity in the harsh space environment.

- Industrial Control Systems: In demanding industrial applications, Honeywell's MRAM is also used as non-volatile storage in data loggers and controllers to ensure stable operation even under extreme temperatures or electromagnetic interference.

TrustCompo recommends the following MRAM, guaranteed for quality and with a competitive price.

Technical Challenges and Future Outlook

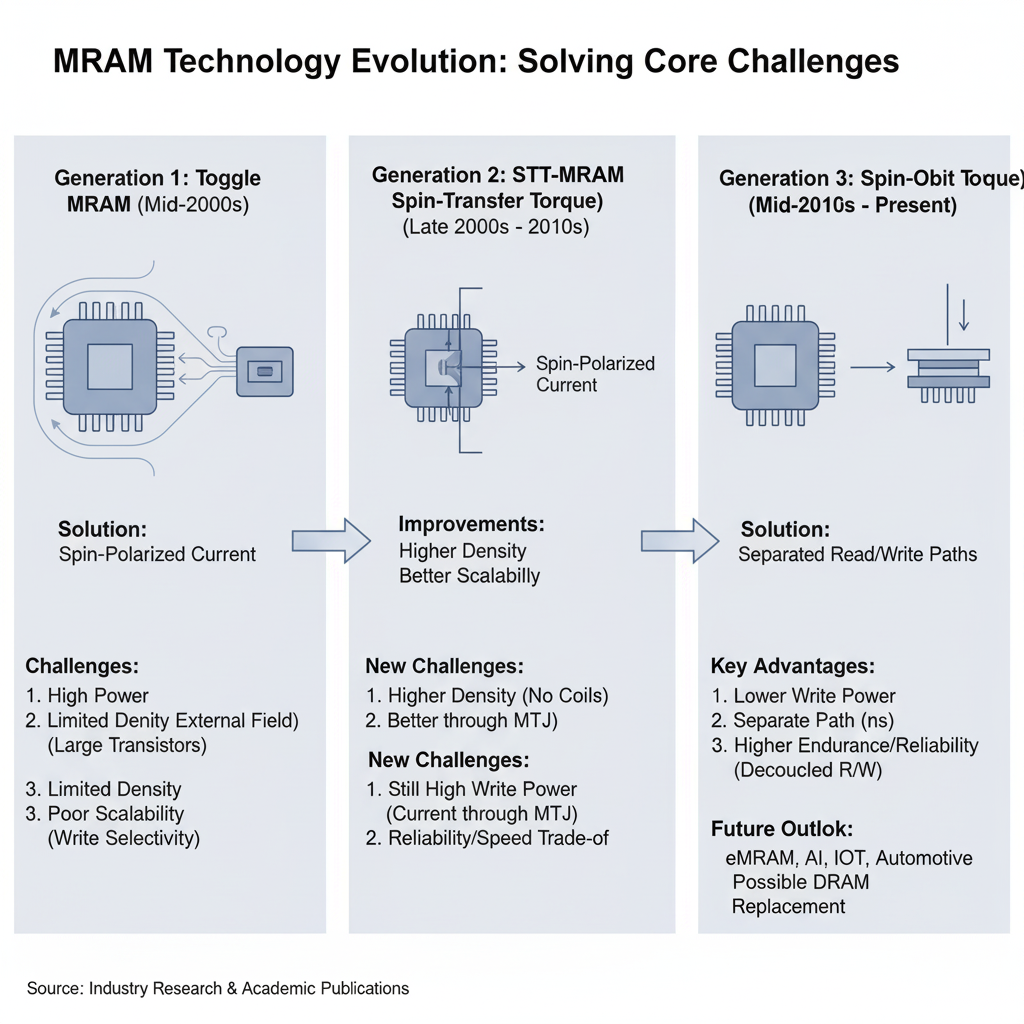

Let's look at the development progress of three generations of MRAM.

Despite significant progress, the commercialization and widespread adoption of MRAM still face some challenges.

Technical Challenges

- Scaling and Integration: While STT-MRAM and SOT-MRAM have made great progress in scaling, maintaining the stability, capacitance, and resistance of MTJ cells at smaller sizes remains a challenge.

- Write Efficiency and Power Consumption: SOT-MRAM still needs further improvements in write efficiency to make its power consumption competitive in more application scenarios.

- CMOS Process Compatibility: The manufacturing process for MRAM cells is different from standard CMOS logic processes. Perfectly integrating MRAM into existing chip manufacturing flows without affecting performance and yield is a complex challenge.

- Price: The per-bit storage cost of MRAM is currently higher than that of DRAM and NAND Flash, which limits its large-scale application in the consumer market.

Future Outlook

The future development of MRAM is full of potential, especially in the following areas:

- Embedded MRAM (eMRAM): MRAM is becoming a mainstream choice for embedded memory, replacing traditional eFlash. It will be integrated with logic chips like microcontrollers (MCUs) and AI chips to provide high-performance, low-power, non-volatile storage solutions.

- Next-Generation MRAM Technology: SOT-MRAM is emerging as a research direction for next-generation high-performance MRAM. Future research will focus on finding more efficient spintronic materials and optimizing device structures to further reduce write power and increase write speed.

- Emerging Applications: MRAM's unique advantages make it an ideal choice for IoT devices, wearables, edge computing, and automotive electronics. These applications have strict requirements for low power consumption, non-volatility, and high reliability.

- DRAM Replacement: Although there are still technical and cost challenges, MRAM has the potential to become a strong competitor to next-generation DRAM. Its non-volatility can simplify system design, reduce power consumption, and provide faster boot times.

In summary, MRAM is gradually evolving from a niche market technology into a mainstream storage technology. By addressing power, cost, and integration challenges, it is expected to gain wider adoption in the coming years.

Through this article, we have explored in depth how MRAM helps safeguard aerospace technology. What are your expectations and views on the future applications of MRAM in more fields?